Have you read our latest article on using rubber for tires ? If you have, then you probably know that the current process for processing this material is the result of more than a century of innovation. But what does it consist of? If for Charles Goodyear in the 19th century it was enough to add a little sulfur, today it’s much more complex. A mixture of synthetic and natural rubbers, various acids and even carbon black is used to form a rubber that is soft but will withstand the wear and tear of the road. Some tires even contain canola oil… It is sometimes taken for granted, but as you will discover, there is a lot of work in the rubber of each tire!

As in colonial times, it all starts with a tree, usually the Hevea brasiliensis or rubber tree. This tree, like nearly 200 other plants, including the famous dandelion, produces latex. This liquid is then mixed with acids to solidify it. The resulting paste is cut into sheets before being pressed, dried and distributed around the world. Synthetic rubbers are made from polymers traditionally found in crude oil. In recent years, however, in an effort to reduce their carbon footprint, some rubber manufacturers have turned to vegetable oil. Thus, today, it is possible to find gums made from canola, sunflower, orange or even guayule oil, a small desert shrub with a high concentration of polymers. Whether synthetic or natural, it is these molecules that make rubber perfect for tire manufacturing. If they can be stretched easily, they will return to their original shape as soon as the force is released.

A few ingredients

Once at the tire plant, these raw rubbers are processed into rubber by adding fillers and a variety of chemicals. The fillers give the tire its traction and make it stronger. Carbon black and silica are used extensively, but are often supplemented with natural ingredients such as sawdust, nut shells and even cornstarch. It is also at this stage that the various additives responsible for vulcanization are added. Sulphur is mixed in, as well as antioxidants and antiozonants to protect the tire from sunlight and air damage. It is by changing the proportion of these ingredients that manufacturers are able to make their tires more resistant, less energy consuming and safer. After all these treatments, the tire is finally ready to be extruded into molds and assembled.

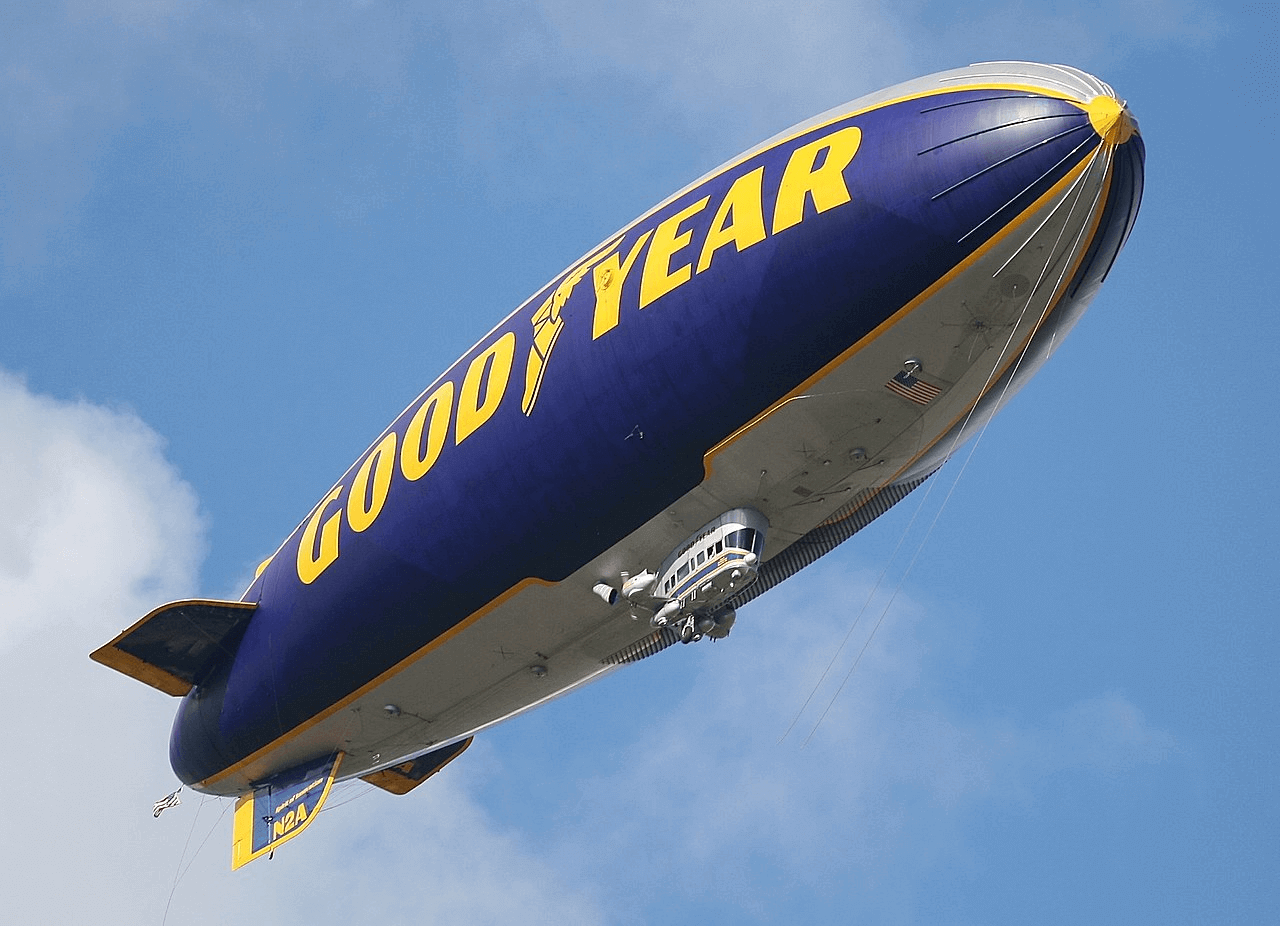

Charles Goodyear didn’t live long enough to see the usefulness of his discovery in the automotive world. However, he was the one who came up with the basic idea of the process that allows you to drive safely on the road. By simply adding a few ingredients to his recipe, it is now possible to make a variety of different gums, adapted to all uses. So the next time you see a tire, think about everything that’s hidden in its rubber. After all, it’s that very same rubber that keeps your car on the road!