The development of a new generation of tires is more than just a matter of design. It's often the result of years, even decades, of research in the fields of chemistry, mechanical engineering and even physics. In a study published in September in the periodical Applied Physics Letters, we can see a direct example of how science can help improve tomorrow's tires. By observing the interaction between two major components of car tire rubber, polybutadiene and carbon black, the researchers' findings could lead to stronger, more efficient tires.

Observing at the atomic level

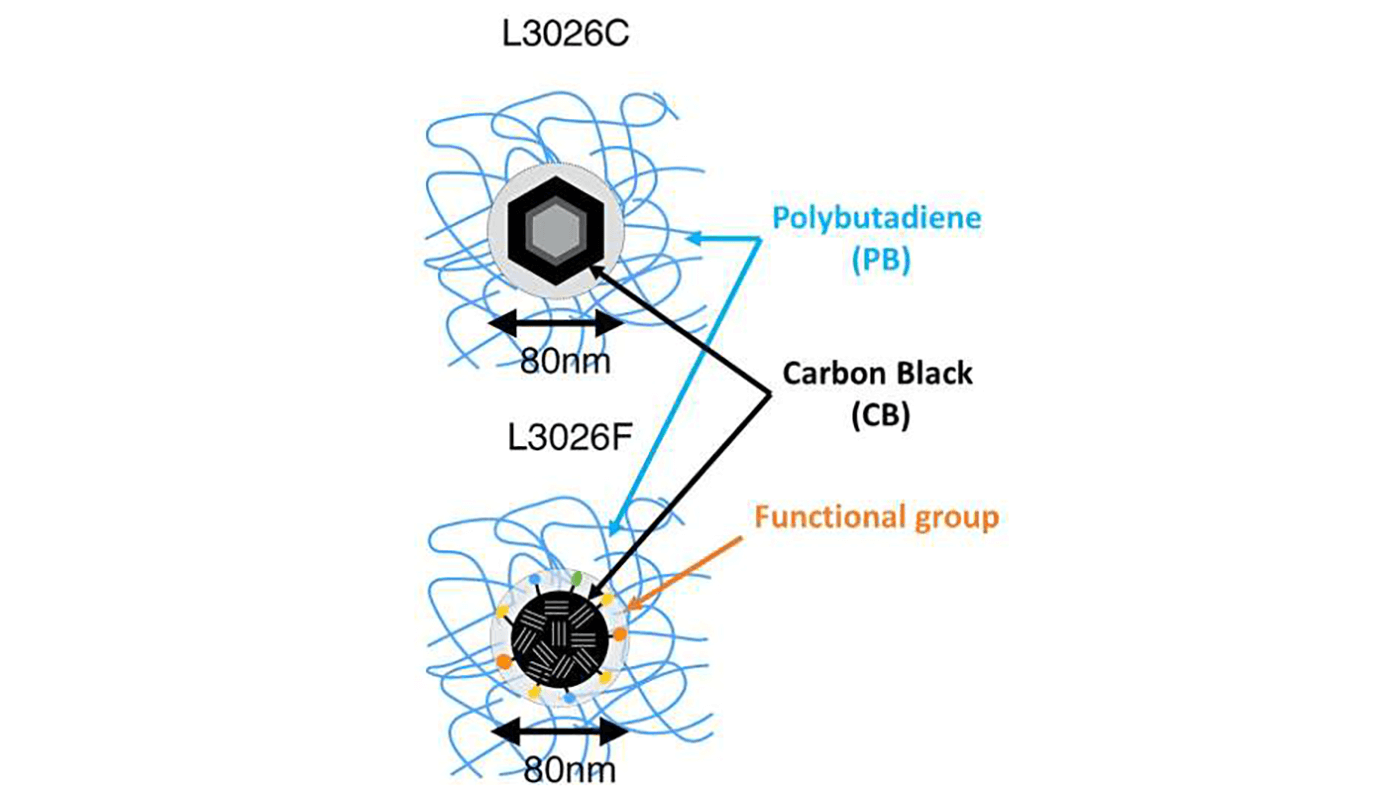

What makes these results so special is the method used by scientists from the University of Tokyo, the University of Ibaraki and the European XFEL, a laser imaging project. Thanks to the latter organization's ultra-sophisticated X-ray equipment, the team was able to observe the friction between polybutadiene molecules and different types of carbon black at the atomic level. Their conclusion? Not all carbon blacks are created equal!

Indeed, when driving, friction with the road causes the two particles to move against each other on a microscopic scale, which can strangely influence tire longevity. With certain types of carbon black, polybutadiene was able to move much more easily. It is therefore said to be more mobile. A more mobile molecule results in a product that deteriorates more easily, which is obviously a problem when most tires today are designed for maximum longevity.

And for the industry?

This study may seem almost insignificant, but the discerning eye can easily recognize its significance for the tire world! In addition to its results, which are certainly very interesting, it is above all its method that could change the game for companies. It would now be possible for the Pirelli, Bridgestone and Michelin companies of this world to check the interaction between the different molecules of their additives in virtually real time. Thanks to these next-generation techniques, they would also be able to customize the characteristics of their rubber at the atomic level, for an even more effective product.

Of course, it will probably be some time before this technology actually makes its way onto the production line, but we have every right to dream! After all, who knows what the next versions of the Yokohama Geolandar or Goodyear Eagle Sport will be like? Better handling and even more robust, they'd be the tires of the future...